Amauchi Industry has experiences in processing the internal parts of precise machine for almost half-century.

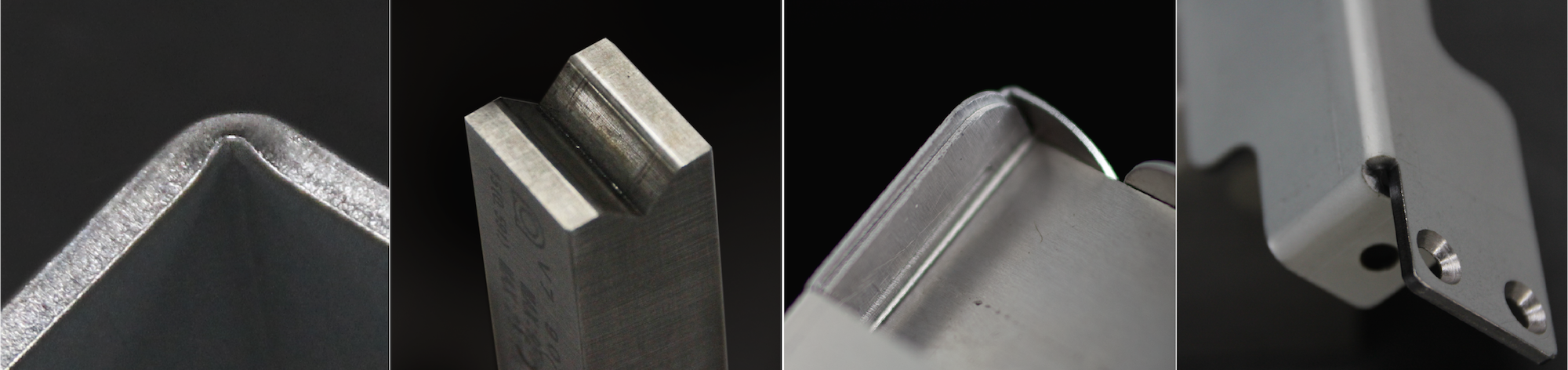

We can process R/Curl bends and complex bending with high precision.The photo shows the internal parts of ATM. The model on the left side is made of plastic, we also offer proposals for the substitute of sheet metal processing.

As the contrast of production planning, the lesser the production, sheet metal processing has better cost

Most of our products are mechanism and interior products,

which will be in the dimension of ±0.1~0.15mm.

| Commercial Tolerance (mm) | |||

| Item \ Dimension | 0.5〜30 | 120 or less | 315 or less |

| Center distance (metal) | ±0.1 | ±0.15 | ±0.2 |

| General dimensions (metal) | ±0.15 | ±0.25 | ±0.4 |

| General dimensions (metal) | ±0.2 | ±0.3 | ±0.5 |

| Bend dimensions | ±0.2 | ±0.3 | ±0.5 |

Parts with difficult shapes or of spring material with a large amount of spring back must also be

“formed into shape” by skilled engineers.

Amauchi Industry is particularly skilled at fabricating items

that may be easy to pressmachine in the mass production stage but that are difficult to fabricate when making a recision prototype by hand from sheet metal.

Thus, when you want to confirm a shape

in the prototype stage of a difficult to fabricate piece,

let us handle the prototype fabricating for you.

We can provide support with simple,

temporary dies for prototypes that require

unique bend machining such as temporary contraction

and curl bends, and we can help you minimize

your prototyping and development costs.

We have put efforts in processing robot parts. Precision sheet metal processing is effective for the wide variety small lot of robots. To improve the control of accuracy, it is necessary to raise the precision of components. The photo shows the communication robot, the parts are made of titanium sheet metal processing. The precision is ±0.1 mm.

We believe precision sheet metal connects to the future.

- A1100P -

| NAME | MACHINE | Sheet thickness(mm) | ||

| Min | ~ | Max | ||

| Aluminum sheet | LAS | - | ||

| NCT | 0.5 | ~ | 6 | |

| BND | 0.5 | ~ | 6 | |

- A5052P -

| NAME | MACHINE | Sheet thickness(mm) | ||

| Min | ~ | Max | ||

| Corrosion- | LAS | 0.5 | ~ | 5 |

| resistant | NCT | 0.5 | ~ | 6 |

| aluminum sheet | BND | 0.5 | ~ | 6 |

- C1100P -

| NAME | MACHINE | Sheet thickness(mm) | ||

| Min | ~ | Max | ||

| Copper sheet | LAS | - | ||

| NCT | 0.5 | ~ | 6 | |

| BND | 0.5 | ~ | 6 | |

- C2801P -

| NAME | MACHINE | Sheet thickness(mm) | ||

| Min | ~ | Max | ||

| Brass sheet | LAS | 0.2 | 〜 | 2 |

| NCT | 0.5 | 〜 | 5 | |

| BND | 0.2 | 〜 | 5 | |

- C5191P -

| NAME | MACHINE | Sheet thickness(mm) | ||

| Min | ~ | Max | ||

| Phosphor-bronze | LAS | 0.2 | ~ | 2 |

| sheet | NCT | 0.5 | ~ | 2 |

| BND | 0.2 | ~ | 2 | |

- C5210P -

| NAME | MACHINE | Sheet thickness(mm) | ||

| Min | ~ | Max | ||

| Phosphor-bronze | LAS | 0.2 | ~ | 2 |

| spring material | NCT | 0.5 | ~ | 2 |

| BND | 0.5 | ~ | 2 | |

- SECC -

| NAME | MACHINE | Sheet thickness(mm) | ||

| Min | ~ | Max | ||

| Steel,Electrically | LAS | 0.5 | ~ | 3.2 |

| Chromate coated | NCT | 0.5 | ~ | 3.2 |

| BND | 0.5 | ~ | 3.2 | |

- SPCC / SPHC -

| NAME | MACHINE | Sheet thickness(mm) | ||

| Min | ~ | Max | ||

| Steel sheet | LAS | 0.4 | 〜 | 6 |

| NCT | 0.5 | 〜 | 6 | |

| BND | 0.4 | 〜 | 6 | |

- SUS304-CP -

| NAME | MACHINE | Sheet thickness(mm) | ||

| Min | ~ | Max | ||

| Stainless sheet | LAS | 0.3 | 〜 | 6 |

| NCT | 0.5 | 〜 | 2.5 | |

| BND | 0.3 | 〜 | 6 | |

- SUS304-CSP -

| NAME | MACHINE | Sheet thickness(mm) | ||

| Min | ~ | Max | ||

| Stainless spring material | LAS | 0.1 | 〜 | 2 |

| NCT | 0.5 | 〜 | 2 | |

| BND | 0.1 | 〜 | 2 | |

- SUS430-CP -

| NAME | MACHINE | Sheet thickness(mm) | ||

| Min | ~ | Max | ||

| Stainless sheet | LAS | 0.3 | 〜 | 6 |

| NCT | 0.5 | 〜 | 2.5 | |

| BND | 0.3 | 〜 | 6 | |

| PROCESS | MACHINE | MAKER | FACILITIES | -- |

| Programming CAD / CAM |

2DCAD / CAM | AMADA | AP100 | 1 |

| 2DCAD / CAM | AP100 JWL | 1 | ||

| 3DCAD | Sheet works for unfold (Bass CAD : Solid worls2015) | 1 |

| PROCESS | MACHINE | MAKER | FACILITIES | -- |

| Blanking process | Punching machine with network control | AMADA | PEGA・345 | 1 |

| Laser | LC1212αⅣ | 1 | ||

| Shirring machine | M1245 | 1 |

| PROCESS | MACHINE | MAKER | FACILITIES | -- |

| Press process | Pr150t ess | AMADA | HY-FLEX PRESS NC1-150 | 1 |

| CB-83 | 1 |

| PROCESS | MACHINE | MAKER | FACILITIES | -- |

| Bending process | Bender machine with NC 80t | AMADA | FBDⅢ-8020NT | 1 |

| Bender machine with NC 35t | FMBⅡ3613NT | 1 | ||

| Bender machine 50t | RG50(with NC9 MINI) | 4 | ||

| Bender machine 35t | RG35 | 4 |

| PROCESS | MACHINE | MAKER | FACILITIES | -- |

| Secondary operation | Deburring machine | Authen TEC | AuDeBu1000 | 1 |

| NC Tapping machine | AMADA | CTS-900 | 1 | |

| Tapping machine | Brother | BT1-203 | 2 | |

| Radial drilling machine | KIRA | KRTG-420 | 2 | |

| Bench drilling machine | KIWA | TB-13 | 4 | |

| barrel polishing machine | UJIDEN | TMB-1 | 1 | |

| high-speed cutting machine | HEIWA | FINE CUT | 1 | |

| Precision cutoff machine | 1 | |||

| Rivetting machines | YOSHIKAWA | US-70 | 2 | |

| wire-electrical discharge machine | Mitsubishi | PX50 | 1 | |

| SetPress | AMADA | SP-30 | 1 | |

| Lathe turning machine | TAKISAWA | TSL−550d | 1 | |

| Abzol washer | 1 |

| PROCESS | MACHINE | MAKER | FACILITIES | -- |

| Welding | Inverter spot welding machine | AMADA | 3 | |

| Spot welding machine | SANYO | SY19 | 1 | |

| MICRO SPOT WELDER | SEIWA MFG | SW-6 | 1 | |

| TIG welder | HITACHI | INVERTER PAIR 200GP5 | 1 | |

| CO2/MAG | INVERTER TRANSUSTOR SWITCHING AUTO TAC 200 | 1 |

| PROCESS | MACHINE | MAKER | FACILITIES | -- |

| Measuring instrument | Digital height gauge | Mitsutoyo | QM-Height 600 | 1 |

| Digital height gauge | Mitsutoyo | HDS-HC | 13 | |

| height gauge | Mitsutoyo | 8 | ||

| Digital Vernier caliper | Mitsutoyo | CD-30C | 18 | |

| Digital Protractor | Marui keiki | 3 | ||

| Stone surface plate | Onishi | 10 | ||

| Pin gauge | Aizen | 1set | ||

| Plug gauge | 1set | |||

| Block gauge | Mitsutoyo | 1set | ||

| Torque driver | Tonishi | 4 | ||

| Dial gauge | Mitsutoyo | 26 | ||

| Thread plug gauge | Sigo | 1set | ||

| Micrometers | Mitsutoyo | 4 |

- To manufacture the small, medium-lot of mass production by

less mold, we utilize the newest equipment of Laser beam

machine, Bunch turret press, Servo vendor, etc, and restrain of the

experiment manufacturing fee.

- Skilled technician will meet the demands of clients. We have

achievement on drawing compound.

- Our company provides design proposal and advices to

simplified the shapes and cut down on the number of components.

- By the coordinating with cooperative companies, we design and

manufacture high precision metal dies with the newest machining

center equipment and processes. Our design includes single shot

and scudding dies.

- We offer prompt maintenance and repair/alteration services for

our dies.

- We can procure and sub-contract other processes to provide a

one-stop solution for assembled components.

To incarnate the needs of customer,

employee, cooperative company,

and society through precision sheet metal technique.

【To be the most trusted high-precision sheet metal engineering company in the world】

Amauchi Industry is the precision sheet metal company, keep improving the technique and quality since 1958.

Although the precision sheet metal technique is not simple, through our creativity and efforts, we assure our high precision and high quality technique. Especially the bending processing technique with high precision combined by the NC machine and craftsmanship has earned the reputation from the customers.

We believe manufacturing is not only “providing speed, price, and quality” of products,

but consider to weight saving and energy saving for the environment is also essential,

which is also our strength. Amauchi Industry provides the technique to help the society.

We believe to become a company that is trustable.

To understand “the needs of customers” and provide the solution. As the world is improving and progressing, we listen to the voice of customers and challenging to become the trusted precision sheet metal technique in the world.

CEO

Miwa Amauchi

![]()

We provide

the products

and services through

our high manufacture

technique and quality.

To solve the problems

and offer the necessary

technique, we continue

developing and

researching.

We put effort on

creating valuable

and safety work

environment.

We value “Quality then

scale, expand the result”

match the environment

for management

and improvement.

We contribute to the

society and thorough

the compliance

for growing.